Cellulose-based food packaging has significant importance in reducing plastic pollution and also ensure our safety from microplastics. Nonetheless, lignocellulose necessitates sophisticated physical and chemical treatments to be fashioned into a satisfactory food packaging, thus leading to extra consumption and operations. The unevenness of bacterial cellulose (BC) film poses significant challenges to its application in food packaging as it can cause stress concentration and a reduction in the film's barrier properties. But during traditional static fermentation of BC film the bacterium will aggregate, which in turn causes the synthesized BC film to be uneven. By treating Komagataeibater sucrofermentans seed with cellulase before inoculation, we previously reduced the local aggregation of the bacteria and synthesized a uniform BC film. Despite its effectiveness, the applications of the cellulase treatment strategy is limited due to its complicated operation and expensive cost.

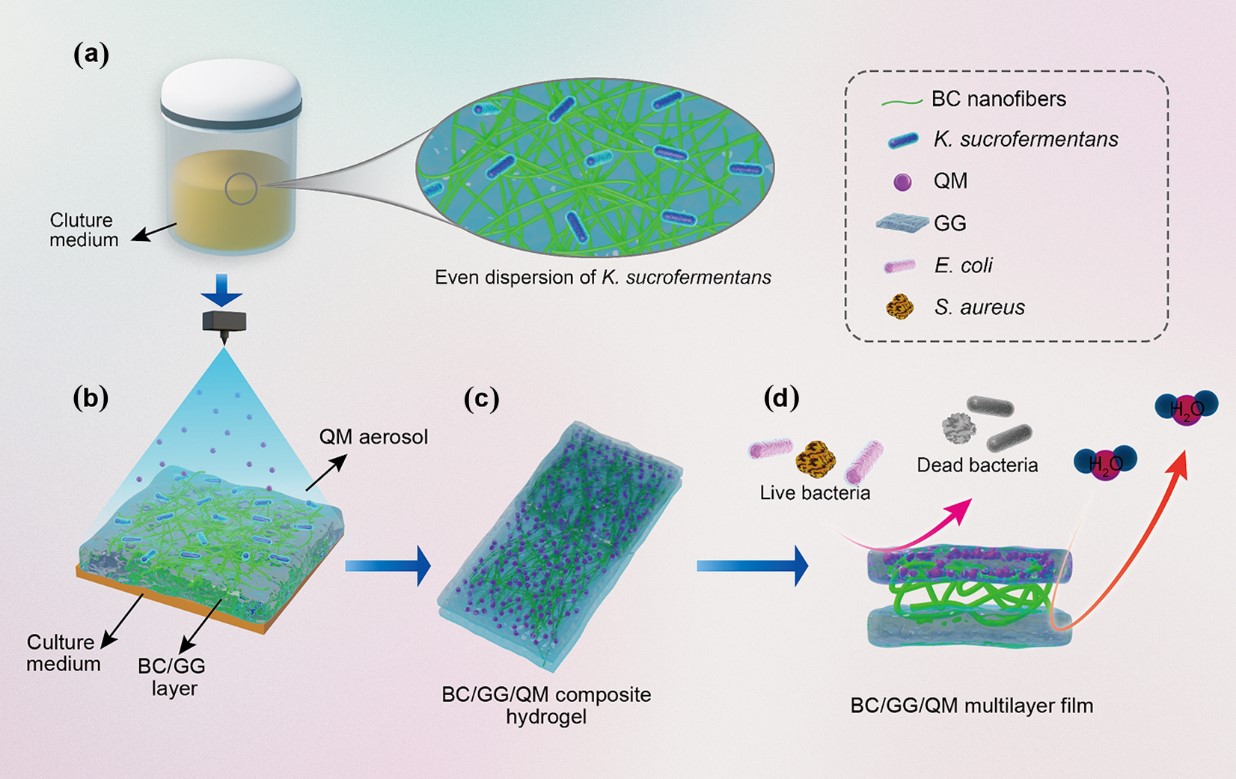

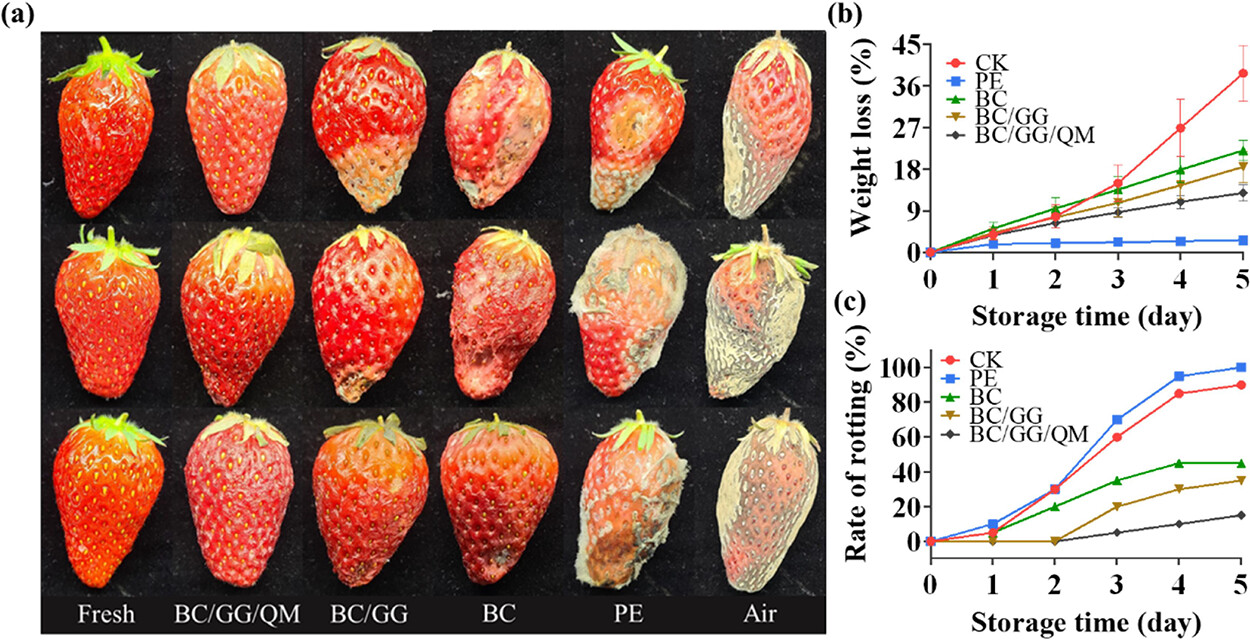

Here we present an gel-assisted biosynthesis approach for in situ production of BC that can be directly applied to food packaging (Figure 1). The K. sucrofermentans is homogeneously distributed in the gellan gum (GG)-assisted culture system, and the BC/GG film with an even surface is attained. Then, the BC/GG film is integrated with an antibacterial layer contains quaternary ammonium chitosan microsphere (QM) through in situ spray biosynthesis method. The resulted BC/GG/QM multilayer film combines the barrier properties and antibacterial activity. The method for in situ biosynthesis is green, efficient and convenient to endow the multilayer film with excellent barrier capacity (1.76 g·mm·m-2·d-1·KPa-1 at RH 75%), high mechanical properties (strength 462 MPa) and antibacterial activity (>90% against Escherichia coli O157:H7 and Staphylococcus aureus). In terms of food preservation, the overall performance of the BC/GG/QM multilayer film is better than commercial petroleum-based film and lignocellulose derived film (Figure 2). This work proffers a novel strategy to produce more beneficial and eco-friendly multilayer film via in situ biosynthesis, which manifests great utility in the field of food packaging.

Figure 1. Fabrication of the bacterial cellulose (BC) /gellan gum (GG) / quaternary ammonium chitosan microsphere (QM) multilayer film

Figure 2. The effects of different films on strawberry preservation

The multilayer film has proven to be an effective replacement for plastic food packaging, addressing the rising concerns of food safety, public health, and sustainable development of film. The corresponding authors of this article are researcher Zhang Haibo, associate researcher Wang Lei and professor Li Qingtao. The authors acknowledge the financial support provided by Shandong Provincial Natural Science Foundation, Research and Innovation Fund of Shandong Energy Institute, National Natural Science Foundation of China, Young Taishan Scholar Sunder Grant, and Youth Innovation Promotion Association, CAS.

Link: https://pubs.acs.org/doi/full/10.1021/acsami.3c10563