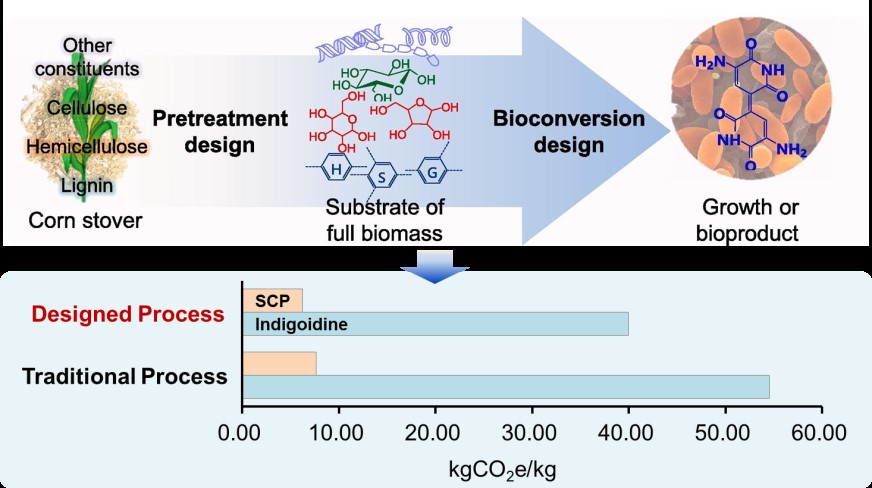

In this study, a whole process design strategy was validated via converting full corn stover into single cell protein (SCP) and blue pigment indigoidine, respectively. The corresponding reduction in CO2 emissions was assessed using life cycle assessment (LCA). By optimizing alkali treatment conditions, the depolymerization of full corn stover was streamlined from a traditional 12-step process to a more efficient 4-step One-Pot Process, incorporating in-situ lignin depolymerization. The optimized One-Pot Process using 0.1 g/g NaOH at 100◦C depolymerized full components of corn stover, and provided a balanced nutrition profile. The selected robust strain Rhodosporidium toruloides converted the components of depolymerized full corn stover to higher SCP and indigoidine compared to equivalent glucose, with the SCP and indigoidine yield reaching 208 g/kg and 72 g/kg, respectively. Furthermore, the LCA results demonstrated that the One-Pot Process reduced CO2 emissions by 18% and 27% compared to traditional processes for SCP and indigoidine production, respectively. This study suggests a systematic design of the whole process for bioconverting full biomass components into bioproducts can simplify the pretreatment operations, enhance product yield, and reduce carbon emissions.

This work was supported by grants from the National Natural Science Foundation of China, National Key R&D Program of China and Natural Science Foundation of Shandong Provincial.

Link: https://doi.org/10.1016/j.cej.2025.160911